Powder for Additive Manufacturing

Osprey® metal powder for Additive Manufacturing is characterized by a spherical morphology and high packing density, which confer good flow properties. For powder bed processes these are essential when applying fresh powder layers to the bed to ensure uniform and consistent part build.

For blown powder processes, such as Direct Energy Deposition (DED), good flow ensures uniform build rates. Tight control of the particle size distribution also helps ensure good flowability. Low oxygen powders result in clean microstructures and low inclusion levels in the finished parts.

Powder for Cold spray

Osprey® metal powder for cold spray is characterized by a spherical morphology and good flow properties. Accurate control of the powder composition and particle size distribution ensure consistent performance both throughout a single batch as well as between different batches of the same alloy.

Powder for Hot Isostatic Pressing (HIP)

Osprey® HIP powder has a spherical morphology, resulting in high packing density. In addition, the powder has a low oxygen content and low impurity levels, resulting in a metallurgically clean product with enhanced mechanical performance.

Powder for Metal Injection Moulding (MIM)

Osprey® MIM powder has a spherical morphology, resulting in high packing density. This enables the manufacture of feedstocks with high powder loading, which not only minimizes binder costs but also reduces part shrinkage during debinding and sintering. Spherical powder also has excellent flow characteristics, resulting in reduced tool wear and consistent mould filling.

Osprey® MIM powder's low oxygen content allows better control of carbon and consistency during sintering. Low oxygen levels, together with high packing density, also facilitate faster sintering.

Powder for Micro-MIM

Osprey® Micro-MIM powder has a spherical morphology, resulting in high packing density. This enables the manufacture of feedstocks with high powder loading, which not only minimizes binder costs but also reduces part shrinkage during debinding and sintering. Spherical powder also has excellent flow characteristics, resulting in reduced tool wear and consistent mould filling.

Osprey® Micro-MIM powders' low oxygen content allows better control of carbon and consistency during sintering. Low oxygen, together with high packing density, also facilitates faster sintering

Powder for sintered metal filters and foams

Osprey® metal powder for sintered metal filters and foams is characterized by a spherical morphology, which results in excellent packing density during processing. Accurate control of the powder composition and particle size distribution ensure consistent performance both throughout a single batch as well as between different batches of the same alloy.

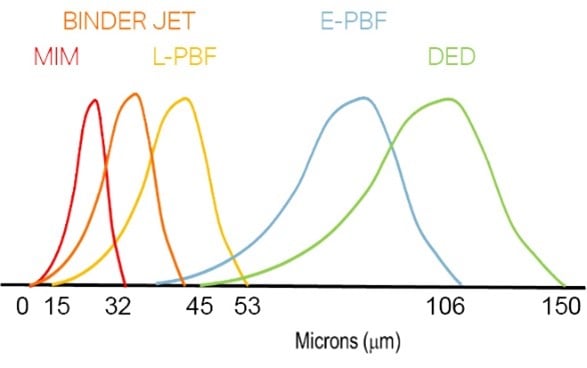

Typical particle size distributions for Additive Manufacturing.

Typical particle size distributions for Additive Manufacturing.