Austenitic stainless steel

Osprey® PANACEA

Osprey® PANACEA is a nickel-free, high-nitrogen austenitic stainless steel.

- EN Name

- X15 CrMnMoN 17-11-3

- AFNOR

- X15 Cr Mn Mo N 17 11 3

Powder designed for

- Additive Manufacturing (AM)

- Metal Injection Moulding (MIM)

This metal powder is manufactured by Inert Gas Atomization (IGA), producing a powder with a spherical morphology which provides good flow characteristics and high packing density.

-

Product description

Osprey® PANACEA is a nickel-free, high-nitrogen austenitic stainless steel. This metal powder is manufactured by Inert Gas Atomization (IGA), producing a powder with a spherical morphology which provides good flow characteristics and high packing density. In addition, the powder has a low oxygen content and low impurity levels, resulting in a metallurgically clean product with enhanced mechanical performance.

Technical data

-

Chemical composition (nominal), %

- Fe

- Bal.

- Cr

- 16.5-17.5

- Mn

- 10.5-11.5

- Mo

- 3.0-3.5

- Si

- 0.40-0.80

- O

- <0.2>

- C

- ≤0.05

- P

- ≤0.04

- S

- ≤0.04

- Ni

- ≤0.10

- Other

- Co ≤0.05, N 0.15-0.60, Nb ≤0.73

-

Powder characteristics and morphology

Powder for Additive Manufacturing

Osprey® metal powder for Additive Manufacturing is characterized by a spherical morphology and high packing density, which confer good flow properties. For powder bed processes these are essential when applying fresh powder layers to the bed to ensure uniform and consistent part build.

For blown powder processes, such as Direct Energy Deposition (DED), good flow ensures uniform build rates. Tight control of the particle size distribution also helps ensure good flowability. Low oxygen powders result in clean microstructures and low inclusion levels in the finished parts.

Powder for Metal Injection Moulding (MIM)

Osprey® MIM powder has a spherical morphology, resulting in high packing density. This enables the manufacture of feedstocks with high powder loading, which not only minimizes binder costs but also reduces part shrinkage during debinding and sintering. Spherical powder also has excellent flow characteristics, resulting in reduced tool wear and consistent mould filling.

Osprey® MIM powder's low oxygen content allows better control of carbon and consistency during sintering. Low oxygen levels, together with high packing density, also facilitate faster sintering.

-

Particle size distribution

Powder for Additive Manufacturing

Osprey® metal powder for Additive Manufacturing is available in a wide range of particle size distributions that are tailored to the individual Additive Manufacturing systems. They can also be tailored to the particular requirements of the end application, both in terms of mechanical performance and surface finish.

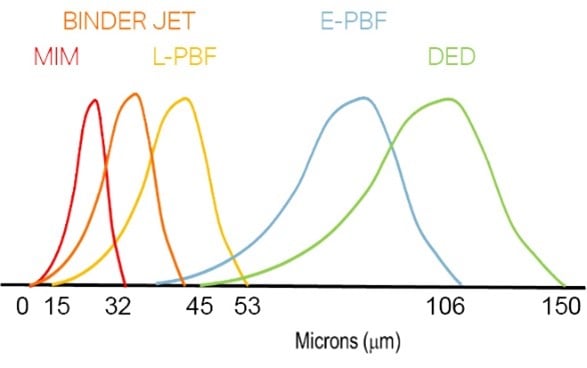

Typical particle size distributions for Additive Manufacturing.

Typical particle size distributions for Additive Manufacturing.Typical particle size distributions for Additive Manufacturing Process technology Size (µm) Binder jetting ≤ 16, ≤ 22, ≤ 32, ≤ 38, ≤ 45 Laser - Powder Bed Fusion (L-PBF) 15 to 53 and 10 to 45 Electron beam - Powder Bed Fusion (E-PBF) 45 to 106 Direct Energy Deposition (DED) 53 to 150 Powder for Metal Injection Moulding (MIM)

Osprey® metal powder for Metal Injection Moulding (MIM) is available in a wide range of particle size distributions, from under 5 μm up to 38 μm. The table shows our standard particle size distributions for MIM powders.

Size (μm) D10 (μm) D50 (μm) D90 (μm) Typical particle size distributions for Metal Injection Moulding (MIM)* ≤ 38 5.5 13.0 31.0 ≤ 32 5.0 12.0 29.0 80% ≤ 22 4.5 11.5 27.0 90% ≤ 22 4.0 10.5 22.0 90% ≤ 16 3.5 8.0 16.0 * Particle size measurements performed using a Malvern laser particle size analyzer, typical D10, D50 and D90 provided.

Tailor-made particle size distributions are available on request. Contact us to discuss your specific requirements.

-

Mechanical properties

Mechanical properties, metric units Condition Proof strength Tensile strength Elongation Hardness Rp0.2 Rm A HV MPa MPa % MIM sintered 690 1090 35 270 Mechanical properties, imperial units Condition Yield strength Tensile strength Elongation, % Hardness Rp0.2 Rm A HV ksi ksi % Msi MIM sintered 100.1 158.1 35 270 -

Physical properties

Density 7.5 g/cm3 (0.271 lb/in3) Porosity 3% Melting point Solidus: ~1365°C, liquidus: ~1450°C. -

Sintering

Osprey® PANACEA has been industrialiZed for MIM, which has a defined production process including sintering temperature and time profile.

- Sintering at atmospheric pressure: 1000mbar 75% N2/ 25% H2

- Partial pressure sintering: 800mbar 100% N

- Typical sintering cycle: 5 K/min to 600 °C, 1 h hold, 600 °C, 5 K/min to 1250 °C, 6 h hold at 1250 °C, then cooling as fast as possible

A post-sintering solution anneal and a rapid cooling (>150 °C/min.) based on an inert gas quench is necessary to create an austenitic microstructure (non-magnetic) and avoid surface chromium nitride precipitation.

-

Testing

All Osprey® metal powders are supplied with a certificate of analysis containing information on the chemical composition and particle size distribution. Information on other powder characteristics is available upon request.

-

Packaging

A wide range of packaging options is available, from 5kgs plastic bottles to 250kg metal drums.

5 kg (11 lbs) Plastic bottles

6 kg (13 lbs) Plastic bottles

10 kg (22 lbs) Plastic bottles

20 kg (44 lbs) Metal cans

100 kg (220 lbs) Steel drums

150 kg (330 lbs) Steel drums

250 kg (551 lbs) Steel drums

All packaging materials are suitable for air, sea and road freight.Contact us for more information and to discuss your packaging requirements.

Disclaimer: Data and recommendations are for guidance only, and the suitability of a powder for a specific process or application can be confirmed only when we know the actual conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Osprey® powder.

Range of austenitic stainless steel

| Osprey® | Standards | Fe | C | Cr | Ni | Mo | Si | Mn | S | P | Other | O | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.4882 | UNS S63019 | Bal. | 0.5 | 21 | 4.5 | - | 0.3 | 9.0 | ≤0.05 | ≤0.03 | - | - |

1.4882

|

| 304L | UNS S30400 / S30403 | Bal. | 0.03 | 18.0-20.0 | 8.0-12.0 | - | 1.0 | 2.0 | 0.03 | 0.045 | - | - |

304L

|

| 310S | UNS S31008 | Bal. | 0.08 | 24.0-26.0 | 19.0-22.0 | - | 1.5 | 2.0 | 0.03 | 0.045 | - | - |

310S

|

| 316L | UNS S31600 / S31603 | Bal. | ≤0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | ≤1.0 | ≤2.0 | ≤0.03 | ≤0.045 | N ≤0.10 | - |

316L

|

| 316Ti | UNS S31635 | Bal. | 0.08 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 1.0 | 2.0 | - | - | Ti 0.7,N 0.25 | - |

316Ti

|

| 904L | UNS N08904 | Bal. | 0.02 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | 1.0 | 2.0 | 0.035 | 0.045 | - | - |

904L

|

| HK30 | JIS J92403 | Bal. | 0.25-0.35 | 23.0-27.0 | 19.0-22.0 | 0.5 | 0.75-1.75 | 1.5 | - | - | Nb 1.20-1.50 | - |

HK30

|

| N-50 | UNS S20910 | Bal. | 0.03-0.05 | 20.5-22.0 | 11.7-13.0 | 2.0-2.5 | 0.2-0.6 | 4.0-5.5 | ≤0.015 | ≤0.040 | Ta ≤0.10, Ti ≤0.02, Sn ≤0.03, W ≤0.15, Cu ≤0.75 | - |

N-50

|

| N-60 | UNS S21800 | Bal. | 0.1 | 16.0-18.0 | 8.0-9.0 | - | 3.5-4.5 | 7.0-9.0 | - | - | N 0.08-0.18 | - |

N-60

|

| PANACEA | - | Bal. | ≤0.05 | 16.5-17.5 | ≤0.10 | 3.0-3.5 | 0.40-0.80 | 10.5-11.5 | ≤0.04 | ≤0.04 | Co ≤0.05, N 0.15-0.60, Nb ≤0.73 | <0.2 |

Get in touch with our experts in metal powder today