Duplex stainless steels

Osprey® 2507

Osprey® 2507 is a super-duplex stainless steel with excellent resistance to SCC and very high resistance to pitting and crevice corrosion. It has high resistance to general corrosion and very high mechanical strength.

- UNS

- S32750

- EN Name

- X 2 CrNiMoN 25-7-4

- EN Number

- 1.4410

- SS

- 2328

Powder designed for

- Additive Manufacturing (AM)

- Hot Isostatic Pressing (HIP)

- Metal Injection Moulding (MIM)

This metal powder is manufactured by Inert Gas Atomization (IGA), producing a powder with a spherical morphology which provides good flow characteristics and high packing density.

-

Product description

Osprey® 2507 is a super-duplex (austenitic-ferritic) stainless steel characterized by excellent resistance to stress corrosion cracking (SCC), very high resistance to pitting and crevice corrosion, high resistance to general corrosion and very high mechanical strength.Main characteristics of Osprey® 2507

- Excellent resistance to stress corrosion cracking (SCC) in chloride-bearing environments (PRE no. ∼43)

- Excellent resistance to pitting and crevice corrosion

- High resistance to general corrosion, erosion and corrosion fatigue

- Very high mechanical strength

- Good weldability

This metal powder is manufactured by Inert Gas Atomization (IGA), producing a powder with a spherical morphology which provides good flow characteristics and high packing density. In addition, the powder has a low oxygen content and low impurity levels, resulting in a metallurgically clean product with enhanced mechanical performance.

Technical data

Page updated Jul 17, 2023 1:39 PM CET (supersedes all previous editions)

-

Chemical composition (nominal), %

- Fe

- Bal.

- Cr

- 25

- Ni

- 7

- Mo

- 4

- C

- ≤0.030

- Si

- ≤0.8

- Mn

- ≤1.2

- P

- ≤0.025

- S

- ≤0.015

- N

- 0.3

- Other

- Cu 0.5

-

Powder characteristics and morphology

Powder for Additive Manufacturing

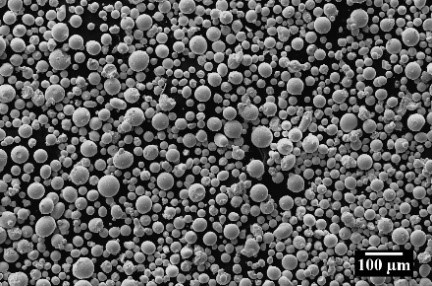

Osprey® metal powder for Additive Manufacturing is characterized by a spherical morphology and high packing density, which confer good flow properties. For powder bed processes these are essential when applying fresh powder layers to the bed to ensure uniform and consistent part build.

For blown powder processes, such as Direct Energy Deposition (DED), good flow ensures uniform build rates. Tight control of the particle size distribution also helps ensure good flowability. Low oxygen powders result in clean microstructures and low inclusion levels in the finished parts.

-53 +15 µm powder with a spherical morphology -53 +15 µm powder with a spherical morphology,

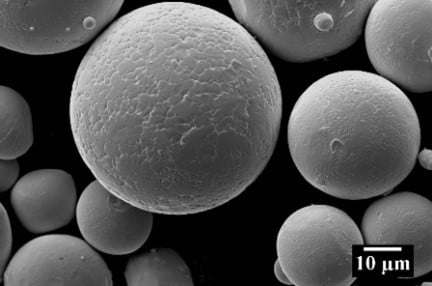

-53 +15 µm powder with a spherical morphology -53 +15 µm powder with a spherical morphology, Smooth surface and low level of powder satellites Smooth surface and low level of powder satellites.

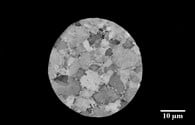

Smooth surface and low level of powder satellites Smooth surface and low level of powder satellites. Powder in cross-section, in back scatted electron mode, highlighting the fine cellular structure.

Powder in cross-section, in back scatted electron mode, highlighting the fine cellular structure.Powder for Hot Isostatic Pressing (HIP)

Osprey® HIP powder has a spherical morphology, resulting in high packing density. In addition, the powder has a low oxygen content and low impurity levels, resulting in a metallurgically clean product with enhanced mechanical performance.

Powder for Metal Injection Moulding (MIM)

Osprey® MIM powder has a spherical morphology, resulting in high packing density. This enables the manufacture of feedstocks with high powder loading, which not only minimizes binder costs but also reduces part shrinkage during debinding and sintering. Spherical powder also has excellent flow characteristics, resulting in reduced tool wear and consistent mould filling.

Osprey® MIM powder's low oxygen content allows better control of carbon and consistency during sintering. Low oxygen levels, together with high packing density, also facilitate faster sintering.

-

Particle size distribution

Powder for Additive Manufacturing

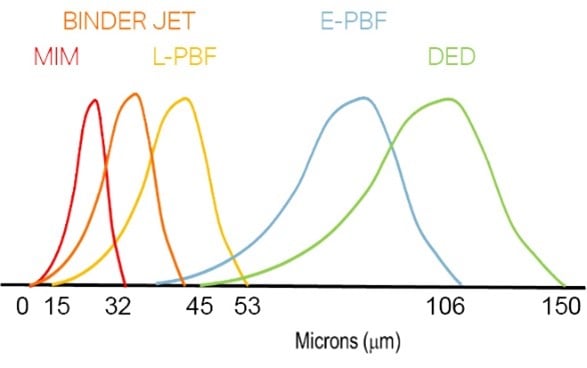

Osprey® metal powder for Additive Manufacturing is available in a wide range of particle size distributions that are tailored to the individual Additive Manufacturing systems. They can also be tailored to the particular requirements of the end application, both in terms of mechanical performance and surface finish.

Typical particle size distributions for Additive Manufacturing.

Typical particle size distributions for Additive Manufacturing.Typical particle size distributions for Additive Manufacturing Process technology Size (µm) Binder jetting ≤ 16, ≤ 22, ≤ 32, ≤ 38, ≤ 45 Laser - Powder Bed Fusion (L-PBF) 15 to 53 and 10 to 45 Electron beam - Powder Bed Fusion (E-PBF) 45 to 106 Direct Energy Deposition (DED) 53 to 150 Powder for Hot Isostatic Pressing (HIP)

Osprey® powder for Hot Isostatic Pressing (HIP) is available in a broad size range, typically <250 microns, resulting in a high packing density and tap density. Low oxygen levels, together with high packing density, also facilitate faster sintering.

Powder for Metal Injection Moulding (MIM)

Osprey® metal powder for Metal Injection Moulding (MIM) is available in a wide range of particle size distributions, from under 5 μm up to 38 μm. The table shows our standard particle size distributions for MIM powders.

Typical particle size distributions for Metal Injection Moulding (MIM)* Size (μm) D10 (μm) D50 (μm) D90 (μm) ≤ 38 5.5 13.0 31.0 ≤ 32 5.0 12.0 29.0 80% ≤ 22 4.5 11.5 27.0 90% ≤ 22 4.0 10.5 22.0 90% ≤ 16 3.5 8.0 16.0 * Particle size measurements performed using a Malvern laser particle size analyzer, typical D10, D50 and D90 provided.

Tailor-made particle size distributions are available on request. Contact us to discuss your specific requirements.

-

Microstructure

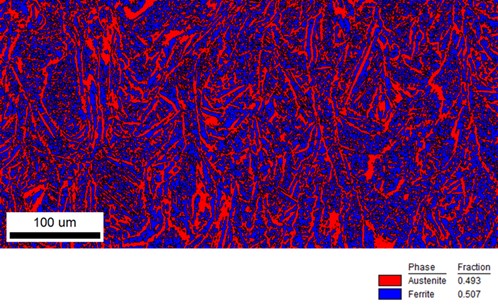

A suitable heat treatment is carried out on the as-built parts in order to achieve the desired austenitic and ferritic microstructure in the final parts. Typically solution annealing between 1,040–1,110 °C (1,904–2,030 °F) followed by air or water cooling is performed.

Micrographs of Osprey® 2507

As-built vertical section of the test specimen with near full dense part with 99.9% + relative density As-built vertical section of the test specimen with near full dense part with 99.9% + relative density.

As-built vertical section of the test specimen with near full dense part with 99.9% + relative density As-built vertical section of the test specimen with near full dense part with 99.9% + relative density. EBSD image indicating phase balance and microstructure in the material after suitable heat treatment EBSD image indicating phase balance and microstructure in the material after suitable heat treatment.

EBSD image indicating phase balance and microstructure in the material after suitable heat treatment EBSD image indicating phase balance and microstructure in the material after suitable heat treatment. -

Mechanical properties

Typical mechanical properties of material produced by Laser - Powder Bed Fusion (L-PBF) in heat-treated condition.

Mechanical properties, metric units Direction Temperature (T), °C Yield strength (Rp0.2), MPa Tensile strength (Rm), MPa E-modulus, GPa Elongation (A), % Horizontal 20 627 956 207 39 Vertical 20 626 923 202 43 Horizontal 100 548 878 205 33 Vertical 100 546 854 205 36 Horizontal 200 505 823 196 30 Vertical 200 504 797 195 31 Horizontal 300 517 857 190 30 Vertical 300 505 832 190 31 Mechanical properties, imperial units Direction Temperature (T), °F Yield strength (Rp0.2), ksi Tensile strength (Rm), ksi E-modulus, ksi Elongation (A), % Horizontal 68 90 138 30 39 Vertical 68 90 133 29 43 Horizontal 212 79 127 30 33 Vertical 212 79 123 30 36 Horizontal 392 73 119 28 30 Vertical 392 73 116 28 31 Horizontal 572 74 124 28 30 Vertical 572 73 121 28 31 Impact strength in heat-treated condition, metric units Direction Temperature (T), °C Impact energy (W), J Horizontal –50 198 Vertical –50 235 Horizontal 0 237 Vertical 0 250 Horizontal 20 242 Vertical 20 247 Horizontal 50 248 Vertical 50 263 Impact strength in heat-treated condition, imperial units Direction Temperature (T), °F Impact energy (W), Ft-lb Horizontal –58 146 Vertical –58 173 Horizontal 32 174 Vertical 32 184 Horizontal 68 178 Vertical 68 182 Horizontal 122 182 Vertical 122 194 Hardness

Typical Vickers Hardness (HV) levels (ASTM E92, ISO 6507-1, JIS Z2244, GB/T 4340.1) as well as HRC values, in the Laser - Powder Bed Fusion (L-PBF) heat-treated condition.

Hardness HV HRC 282 +/–8 29 +/–1 Surface roughness

Measured surface roughness values (ISO 25178-6, ISO25178-606, DIN EN ISO 4287, ISO 4288), Laser - Powder Bed Fusion (L-PBF) heat-treated and

blasted condition.Surface roughness in blasted condition Ra, µm Rz, µm Sa, µm 1.6 7.02 4.8 -

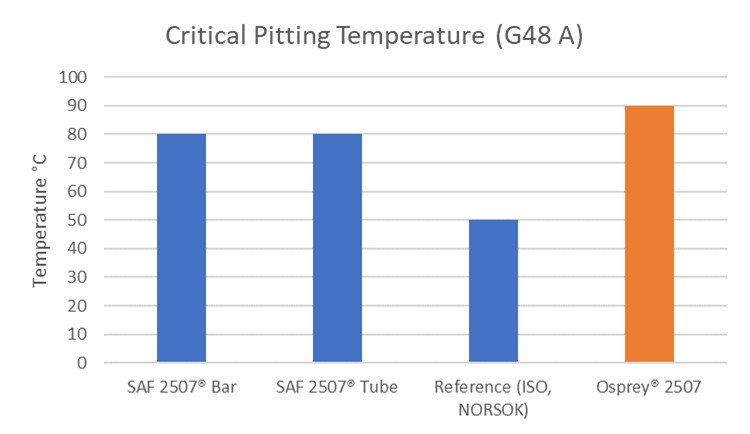

Corrosion properties

Corrosion properties tested on the bulk material as per the ASTM G48 and ASTM G150 standards.

Critical pitting temperature (CPT) in heat-treated condition Standard Temperature (T), °C Temperature (T), °F ASTM G48 90 194 ASTM G150 >95 >203  Graph showing critical pitting temperature for various materials.

Graph showing critical pitting temperature for various materials. -

Typical application areas

Osprey® 2507 powder is typically used in the following areas:

- Oil and gas industry

- Pulp and paper industry

- Chemical industry

- Refineries and petrochemical plants

- On-shore and off-shore industry

Impeller and rotor prototypes.

Impeller and rotor prototypes. -

Testing

All Osprey® metal powders are supplied with a certificate of analysis containing information on the chemical composition and particle size distribution. Information on other powder characteristics is available upon request.

-

Packaging

A wide range of packaging options is available, from 5kgs plastic bottles to 250kg metal drums.

5 kg (11 lbs) Plastic bottles

6 kg (13 lbs) Plastic bottles

10 kg (22 lbs) Plastic bottles

20 kg (44 lbs) Metal cans

100 kg (220 lbs) Steel drums

150 kg (330 lbs) Steel drums

250 kg (551 lbs) Steel drums

All packaging materials are suitable for air, sea and road freight.Contact us for more information and to discuss your packaging requirements.

Disclaimer: Data and recommendations are for guidance only, and the suitability of a powder for a specific process or application can be confirmed only when we know the actual conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Osprey® powder.

Osprey® Online

Buy Osprey® 2507 for additive manufacturing from our online store, available directly from stock.

Range of duplex stainless steel

| Osprey® | Standards* | Fe | Cr | Ni | Mo | C | Si | Mn | P | S | N | Other | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.4091 | EN Number 1.4091 | Bal. | 32-38 | 11-16 | 2.0-4.0 | 1.0- 1.5 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.035 | 0.10-0.40 | W 0.5-2.0 |

1.4091

|

| 2205 | UNS S32205 / S32205 | Bal. | 22 | 5 | 3.2 | ≤0.030 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.015 | 0.18 | - |

2205

|

| 2507 | UNS S32750 | Bal. | 25 | 7 | 4 | ≤0.030 | ≤0.8 | ≤1.2 | ≤0.025 | ≤0.015 | 0.3 | Cu 0.5 | |

| 2707 | UNS S32707 | Bal. | 27 | 6.5 | 4.8 | ≤0.030 | ≤0.5 | ≤1.5 | ≤0.035 | ≤0.010 | 0.4 | Co 1.0 |

2707

|

| 3207 | UNS S33207 | Bal. | 32 | 7 | 3.5 | ≤0.030 | ≤0.8 | ≤1.5 | ≤0.035 | ≤0.010 | 0.5 | - |

3207

|

* Information about more standards is available in the datasheet for the respective alloy.

Get in touch with our experts in metal powder today