Maraging steel

Osprey® MAR-50-Co free

Osprey® MAR-50 Co-free* is a maraging steel free of cobalt, with reduced amount of nickel and an addition of chromium. This alloy also comes in titanium-free variants for improved polishability.

Powder designed for

- Additive Manufacturing (AM)

This metal powder is manufactured by either induction melting under Vacuum Inert Gas Atomization (VIGA) or melting under argon prior to Inert Gas Atomization (IGA).

-

Product description

Osprey® MAR-50 Co-free* is a maraging steel free of cobalt, with reduced amount of nickel and an addition of chromium, to obtain a nearly fully martensitic microstructure already in the Laser - Powder Bed Fusion (L-PBF) as-built condition. We also offer titanium-free variants of this alloy for improved polishability. For more information about titanium-free Osprey® MAR-50 Co-free, please contact us.

Osprey® MAR-50 Co-free is typically used for conformal-cooled mould tooling and rubber-tyre mould (sipes) applications. This alloy has been developed using the latest metallurgical modelling systems. It can be directly aged to achieve levels of material performances including strength, hardness and toughness comparable to the conventional 18Ni300 maraging steel.

This metal powder is manufactured by either induction melting under Vacuum Inert Gas Atomization (VIGA) or melting under argon prior to Inert Gas Atomization (IGA), producing a powder with a spherical morphology which provides good flow characteristics and high packing density. In addition, the powder has a low oxygen content and low impurity levels, resulting in a metallurgically clean product with enhanced mechanical performance.

*This alloy is sometimes referred to as Fe9Ni5Cr1.4Mo0.7Ti

Technical data

Page updated Sep 14, 2023 12:40 PM CET (supersedes all previous editions)

-

Chemical composition (nominal), %

- Fe

- Bal.

- C

- ≤0.06

- Cr

- 4.0

- Ni

- 9.5

- Mo

- 4.5

- Co

- ≤0.1

- Ti

- ≤1.0

- Al

- ≤0.3

- Mn

- ≤0.5

- Si

- ≤0.5

- P

- ≤0.03

- S

- ≤0.03

-

Powder characteristics and morphology

Powder for Additive Manufacturing

Osprey® metal powder for Additive Manufacturing is characterized by a spherical morphology and high packing density, which confer good flow properties. For powder bed processes these are essential when applying fresh powder layers to the bed to ensure uniform and consistent part build.

For blown powder processes, such as Direct Energy Deposition (DED), good flow ensures uniform build rates. Tight control of the particle size distribution also helps ensure good flowability. Low oxygen powders result in clean microstructures and low inclusion levels in the finished parts.

-

Particle size distribution

Powder for Additive Manufacturing

Osprey® metal powder for Additive Manufacturing is available in a wide range of particle size distributions that are tailored to the individual Additive Manufacturing systems. They can also be tailored to the particular requirements of the end application, both in terms of mechanical performance and surface finish.

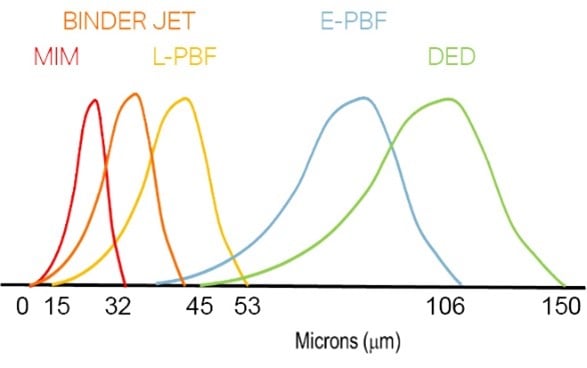

Typical particle size distributions for Additive Manufacturing.

Typical particle size distributions for Additive Manufacturing.Typical particle size distributions for Additive Manufacturing Process technology Size (µm) Binder jetting ≤ 16, ≤ 22, ≤ 32, ≤ 38, ≤ 45 Laser - Powder Bed Fusion (L-PBF) 15 to 53 and 10 to 45 Electron beam - Powder Bed Fusion (E-PBF) 45 to 106 Direct Energy Deposition (DED) 53 to 150 Tailor-made particle size distributions are available on request. Contact us to discuss your specific requirements.

-

Microstructure

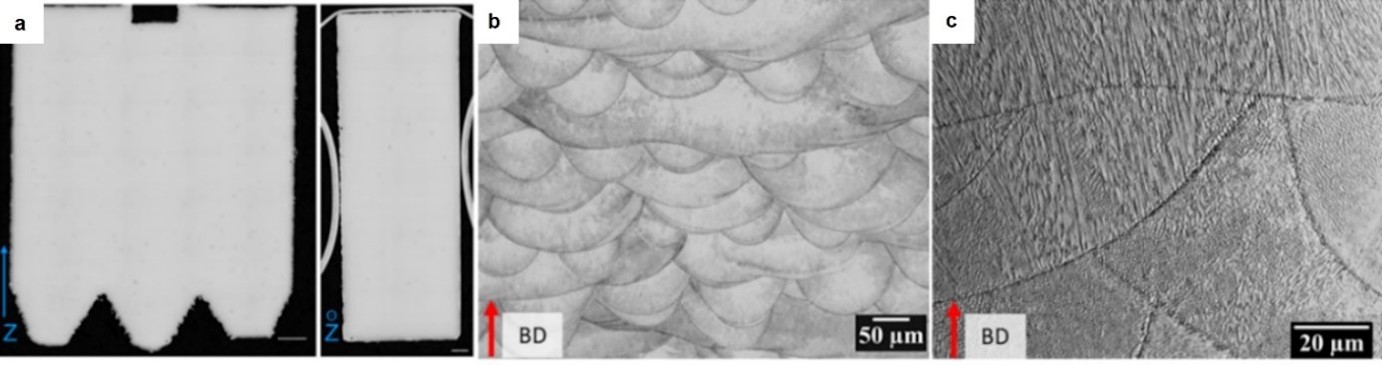

LOM micrographs: a) a low magnification profile of the cross-section along build direction and normal to build direction, b) chemically etched cross-section showing traces of the melt pools, c) higher magnification micrograph showing the ultrafine cellular/dendritic solidification structure.

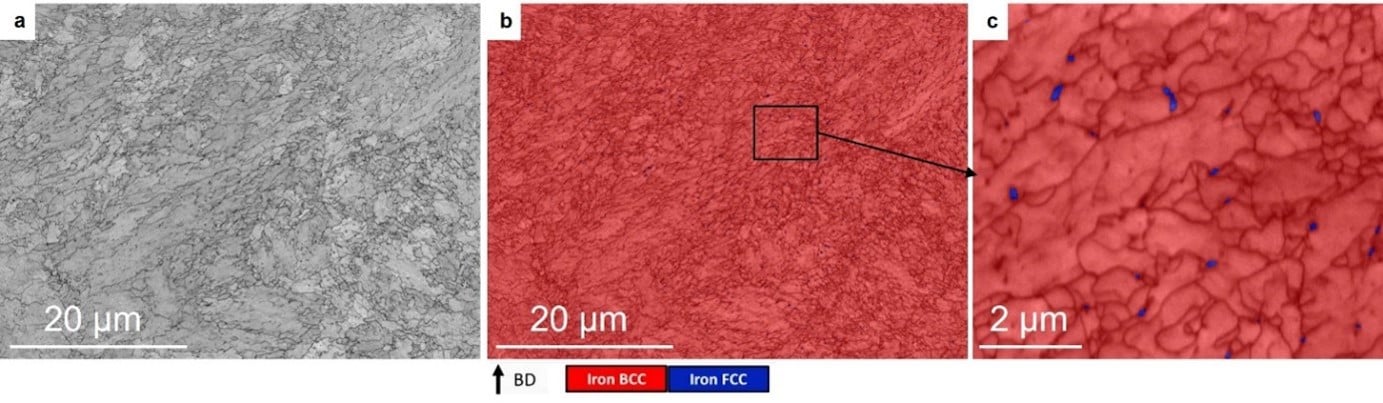

LOM micrographs: a) a low magnification profile of the cross-section along build direction and normal to build direction, b) chemically etched cross-section showing traces of the melt pools, c) higher magnification micrograph showing the ultrafine cellular/dendritic solidification structure.The Electron Beam Back-scatter Diffraction (EBSD) analysis results confirm that the volume fraction of retained austenite (blue areas) is negligible in the as-built condition and the microstructure is essentially martensitic (red areas). This provides a suitable condition for direct ageing of the essentially martensitic as-built microstructure without the need for prior solution annealing.

As-built sample: a) SEM micrograph of Osprey® Co-free maraging steel, b-c) EBSD analysis results, phase maps overlaid on band contrast images, low magnification scan higher magnification scan, respectively, showing the position of retained austenite

As-built sample: a) SEM micrograph of Osprey® Co-free maraging steel, b-c) EBSD analysis results, phase maps overlaid on band contrast images, low magnification scan higher magnification scan, respectively, showing the position of retained austenite -

Mechanical properties

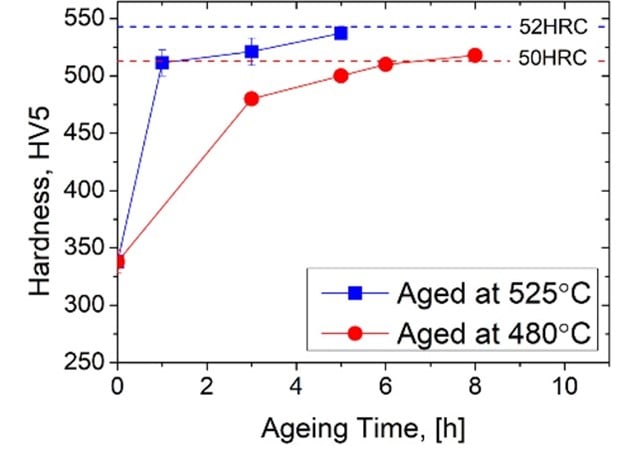

Hardness after ageing at 480 °C/896 °F and 525 °C/977 °F vs. time for samples directly aged.

Hardness after ageing at 480 °C/896 °F and 525 °C/977 °F vs. time for samples directly aged.Typical mechanical properties of material produced by Laser - Powder Bed Fusion (L-PBF) in as-built and directly aged conditions, evaluated at room temperature.

Mechanical properties, metric units Direction Ageing temperature, °C Ageing time, h Yield strength (Rp0.2), MPa Tensile strength (Rm), MPa Elongation (ALO15), % Area reduction, % Hardness, HRC Impact toughness (CVN*), J Vertical As built N/A 1,075 1,095 19 74 35 190 Vertical 480 8.0 1,550 1,620 10 52 50–51 8 Horizontal 480 8.0 1,700 1,730 10.3 52 50–51 14 Mechanical properties, imperial units Direction Ageing temperature, °F Ageing time, h Yield strength (Rp0.2), ksi Tensile strength (Rm), ksi Elongation (ALO15), % Area reduction, % Hardness, HRC Impact toughness (CVN*), ft-lb Vertical As built N/A 156 159 19.0 74 35 140 Vertical ~900 8.0 225 235 10.0 52 50–51 6 Horizontal ~900 8.0 247 251 10.3 52 50–51 10 *CVN = Charpy V-Notched impact toughness test

-

About maraging steels

Maraging steels are a class of ultra-high strength, high hardness and high toughness steels which can be welded without preheating either in annealed (easy to machine) or heat-treated condition. These properties make them ideal candidates for the Laser - Powder Bed Fusion (L-PBF) process to manufacture parts with complex geometries for demanding applications which require an excellent combination of strength, toughness, and thermal stability.

The strengthening mechanisms in this type of steel differ from those in classical carbon steels where martensitic, bainitic or pearlitic phases are formed on cooling and tempering is employed to control carbide precipitation. Less than 50% of the overall contribution to strengthening is provided by the extremely tough Fe-Ni martensite, while aging of this martensite, containing Mo, Al, Ti and Co in supersaturated solid solution, provides additional strengthening by precipitation of nanosized intermetallic particles in the martensitic matrix.

-

Testing

All Osprey® metal powders are supplied with a certificate of analysis containing information on the chemical composition and particle size distribution. Information on other powder characteristics is available upon request.

-

Packaging

A wide range of packaging options is available, from 5kgs plastic bottles to 250kg metal drums.

5 kg (11 lbs) Plastic bottles

6 kg (13 lbs) Plastic bottles

10 kg (22 lbs) Plastic bottles

20 kg (44 lbs) Metal cans

100 kg (220 lbs) Steel drums

150 kg (330 lbs) Steel drums

250 kg (551 lbs) Steel drums

All packaging materials are suitable for air, sea and road freight.Contact us for more information and to discuss your packaging requirements.

Disclaimer: Data and recommendations are for guidance only, and the suitability of a powder for a specific process or application can be confirmed only when we know the actual conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Osprey® powder.

Range of maraging steels

| Osprey® | Standards* | Fe | C | Cr | Ni | Mo | Co | Ti | Al | Mn | Si | P | S | O | N | W | V | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 18Ni300 | UNS K93120 | Bal. | ≤0.03 | ≤0.3 | 18 | 4.8 | 9.0 | 0.7 | 0.1 | - | ≤0.1 | ≤0.01 | ≤0.01 | - | - | - | - |

18Ni300

|

| HWTS 50 | - | - | 0.18-0.25 | 2.5-3.0 | - | 2.0-2.5 | - | - | - | 0.10-0.50 | 0.05-0.50 | - | - | - | < 0.06 | - | 0.4-0.6 |

HWTS 50

|

| MAR-50-Co free | - | Bal. | ≤0.06 | 4.0 | 9.5 | 4.5 | ≤0.1 | ≤1.0 | ≤0.3 | ≤0.5 | ≤0.5 | ≤0.03 | ≤0.03 | - | - | - | - | |

| MAR-60 | ASTM, AISI 13Ni400 | Bal. | ≤0.03 | ≤0.3 | 13.0 | 10.0 | 15.0 | 0.20 | 0.01 | ≤0.1 | ≤0.1 | ≤0.01 | ≤0.01 | ≤0.1 | ≤0.1 | - | - |

MAR-60

|

* Information about more standards is available in the datasheet for the respective alloy.

Get in touch with our experts in metal powder today