Nickel

Osprey® M-400

Osprey® M-400 is a nickel-copper alloy with good corrosion resistance combined with good strength and toughness.

- UNS

- N04400

- ASTM

- B127, F96

- EN Number

- 2.4360, 2.4361

- DIN

- 2.4360, 2.4361

Powder designed for

- Additive Manufacturing (AM)

This metal powder is manufactured by Inert Gas Atomization (IGA), producing a powder with a spherical morphology which provides good flow characteristics and high packing density.

-

Product description

Osprey® M-400 is a nickel-copper alloy with good corrosion resistance – especially in marine, chemical, and oil & gas applications – combined with good strength and toughness. Osprey® M-400 is an alloy of the same type as Monel® 400*.

This metal powder is manufactured by Inert Gas Atomization (IGA), producing a powder with a spherical morphology which provides good flow characteristics and high packing density. In addition, the powder has a low oxygen content and low impurity levels, resulting in a metallurgically clean product with enhanced mechanical performance.

* MONEL® is a trademark of Huntington Alloys Corporation.

Technical data

Page updated May 14, 2024 8:47 AM CET (supersedes all previous editions)

-

Chemical composition (nominal), %

- Ni

- Bal.

- Cu

- 28.0-34.0

- Fe

- ≤2.5

- Si

- ≤0.5

- Mn

- ≤2.0

- C

- ≤0.3

- S

- ≤0.024

-

Powder characteristics and morphology

Powder for Additive Manufacturing

Osprey® metal powder for Additive Manufacturing is characterized by a spherical morphology and high packing density, which confer good flow properties. For powder bed processes these are essential when applying fresh powder layers to the bed to ensure uniform and consistent part build.

For blown powder processes, such as Direct Energy Deposition (DED), good flow ensures uniform build rates. Tight control of the particle size distribution also helps ensure good flowability. Low oxygen powders result in clean microstructures and low inclusion levels in the finished parts.

-

Particle size distribution

Powder for Additive Manufacturing

Osprey® metal powder for Additive Manufacturing is available in a wide range of particle size distributions that are tailored to the individual Additive Manufacturing systems. They can also be tailored to the particular requirements of the end application, both in terms of mechanical performance and surface finish.

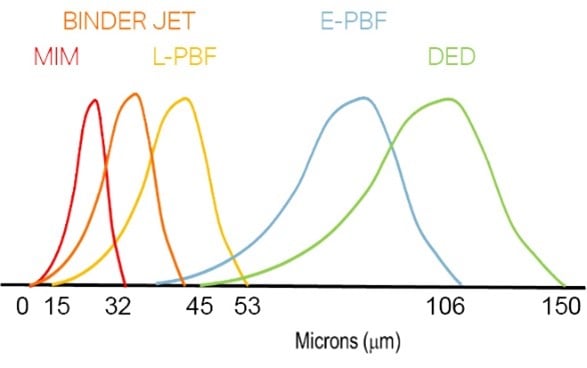

Typical particle size distributions for Additive Manufacturing.

Typical particle size distributions for Additive Manufacturing.Typical particle size distributions for Additive Manufacturing Process technology Size (µm) Binder jetting ≤ 16, ≤ 22, ≤ 32, ≤ 38, ≤ 45 Laser - Powder Bed Fusion (L-PBF) 15 to 53 and 10 to 45 Electron beam - Powder Bed Fusion (E-PBF) 45 to 106 Direct Energy Deposition (DED) 53 to 150 Tailor-made particle size distributions are available on request. Contact us to discuss your specific requirements.

-

Mechanical properties

Processing by Laser - Powder Bed Fusion (L-PBF) is possible for both red and green laser systems, achieving printed densities ~99.8%, 670 MPa UTS, 412 MPa yield, >25% elongation and micro-hardness ~210 HV after heat treatment.1

1 Qualification of a Ni–Cu Alloy for the Laser Powder Bed Fusion Process (LPBF): Its Microstructure and Mechanical Properties. Appl. Sci. 2020, 10(10), 3401. I. Raffeis et al.

-

Testing

All Osprey® metal powders are supplied with a certificate of analysis containing information on the chemical composition and particle size distribution. Information on other powder characteristics is available upon request.

-

Packaging

A wide range of packaging options is available, from 5kgs plastic bottles to 250kg metal drums.

5 kg (11 lbs) Plastic bottles

6 kg (13 lbs) Plastic bottles

10 kg (22 lbs) Plastic bottles

20 kg (44 lbs) Metal cans

100 kg (220 lbs) Steel drums

150 kg (330 lbs) Steel drums

250 kg (551 lbs) Steel drums

All packaging materials are suitable for air, sea and road freight.Contact us for more information and to discuss your packaging requirements.

Disclaimer: Data and recommendations are for guidance only, and the suitability of a powder for a specific process or application can be confirmed only when we know the actual conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Osprey® powder.

Range of nickel alloys

Get in touch with our experts in metal powder today